01.03.2021

Newsbinderholz Project successfully established

"Växjö will get a new municipal and train station building," said a headline in the SVT, Sweden's public TV broadcaster, in November 2018. At that time, the detailed planning was already in full swing, the contract for the planning, delivery and assembly of the entire solid wood shell construction was signed, as well as the static concepts transmitted to our client, the company Skanska.

The binderholz Project offer range of static calculations, detailed drawings and assembly plans for the production and delivery of all solid wood components including suitable fasteners provides significant added value for our customers. In this way, the client receives everything from a single source and has a contact person for all matters. The offer is completed with the assembly of the solid wood raw construction by our competent and experienced assembly partners.

It is always the sales department that lays the foundation for a successful project. After successful project acquisition, we can discuss on an equal footing with the project engineers of our customers and apply the experience of our highly qualified statics and project planning department.

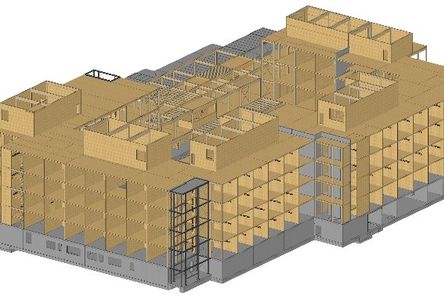

Recently, the binderholz Project department has also succeeded in completing another outstanding project. The Swedish company Parkering Malmö entrusted binderholz with the planning, delivery and installation of a 6-storey car park made of CLT BBS and glulam.

Another flagship project was started "on site" at the beginning of October after 10 months of planning. We will keep ourselves busy on site in Oslo, Norway, for only about 10 months, with the solid wood construction assembly of a kindergarten and retirement home.

In addition, the student dormitory project in As, Norway, was successfully completed. We were able to hand over the project to our customer after 11 months of assembly. The first students moved in in September. A total of 6,500 m3 CLT BBS and glulam were installed, 6,000 running metres of sound insulation bearings were laid and more than 100,000 screws and various fasteners were used.